In point of use/point of entry (POU/POE) water applications, use of activated carbon filter material is widespread. The sort of raw materials used to make Activated Carbon has a significant influence on its properties. Coconut shell and bituminous coal are common.

The Activated Carbon made from coconut shells has the most micropores. Micropores are pores with a dimension of fewer than 20 angstrom units (two nanometers). There are fewer micropores in AC made from bituminous coal, but more macropores and mesopores. Mesopores range in size from 20 to 500 angstrom units (two to 50 nanometers); whereas macropores are larger than 500 angstrom units (50nm).

Coconut shell-based Vs. Bituminous coal-based

Mercury intrusion and nitrogen adsorption are used to determine the volume of different pore diameters. The pore volume findings of mercury intrusion and nitrogen adsorption may be plotted to get a pore volume distribution. Coconut shell-based activated carbon has around 50% more micropores than bituminous coal-based activated carbon.

The ASTM D 4607, standard Test Technique for Determination of Iodine Number of Activated Carbon, ASTM International, is the most widely used method for determining micropore volume. Most of the coconut activated carbon manufacturer use the same methodology. On the other hand, coconut shell activated carbon suppliers also seek high-quality based on ASTM D 4607 Standard Test Technique.

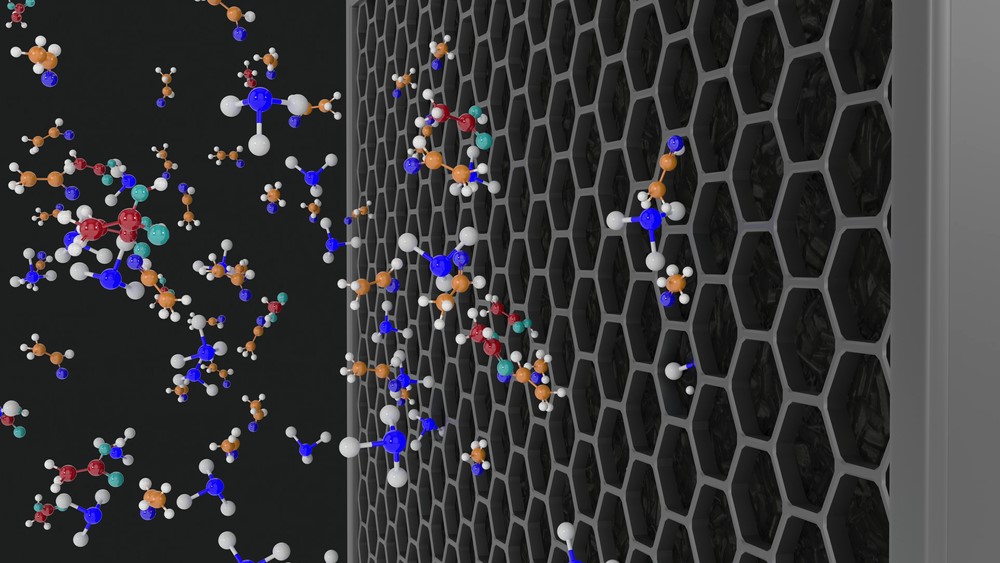

VOC treatment

Most disinfection by-products (DBPs), such as trihalomethanes (THMs), and other VOC pollutants, such as trichloroethylene, are classified as volatile organic compounds (TCE). Many VOCs have a low molecular weight, usually less than 200, and are insoluble in water.

Carbon adsorption isotherms on coconut shell and bituminous coal-based activated carbons were used to determine the AC’s theoretical saturation capacity for VOCs.

The benzene saturation capabilities of the coconut shell-based AC were greater at all benzene concentrations in water.

When compared to bituminous coal-based AC (Activated Carbon), the coconut shell AC had almost twice the saturation capacity, with 11 mg of benzene per gram of coconut shell carbon against six for the coal-based AC. The carbon consumption (exhaustion) rate is calculated in Column 3 of Table 3 using this saturation capacity and a benzene influent of 10 ppb. For every 1,000 gallons of water treated, 0.0076 pounds of coconut shell AC would be expelled against 0.014 pounds of bituminous coal AC. After that, the cost of carbon emitted per 1,000 gallons of treated water was determined. This comparison was made using the prices of acid-washed bituminous coal activated carbon and unwashed coconut shell activated carbon. Unwashed bituminous coal carbon has three times the ash or impurity levels of unwashed coconut shell carbon, thus acid-washed was chosen. When compared to unwashed coconut shell AC, acid-washed bituminous coal AC has two times the ash content. When comparing cleaned bituminous AC to unwashed coconut shell AC in Column 4, the treatment cost is about three times greater, suggesting a considerable cost reduction with coconut shell AC. The MTBE capabilities of the coconut shell-based activated carbon were greater at all MTBE concentrations in water.

Coconut shell carbon had a considerably greater saturation capacity this time. When compared to unwashed coconut shell carbon, this corresponds to a 2.5-fold greater treatment cost with washed bituminous carbon.

In actual full-scale application, the capacity gain demonstrated with coconut shell AC may not always be realized. To some extent, background organics such as total organic carbon (TOC) will reduce the AC’s saturation capacity for a VOC. Low empty bed contact periods (water residence time) in the AC filter will also prevent the carbon from reaching its saturation capacity.

Additional differences

The ASTM hardness number of the two kinds of activated carbon is compared in Table 2. A greater hardness value indicates that there will be less particle attrition and dust. Coconut shell air conditioners use less water to clean (backwash) a fresh bed and produce less particles while in use.

Coconut shell air conditioning is also more ecologically friendly. Coconuts are produced three times a year by the coconut tree. Because the tree is not cut down to gather the coconut shells, it is a renewable resource. Bituminous coal is a non-renewable resource since it takes millions of years to produce. Furthermore, the coconut trees take some of the carbon dioxide created during the production of coconut shell carbon and produce oxygen.

Supply of activated carbon

The United States has two significant domestic producers of bituminous coal-based activated carbon, and bituminous coal-based activated carbon has been widely imported from China over the past two decades. In the last year, this has drastically altered.

In response to a petition filed by domestic producers, the US imposed additional anti-dumping duties on most activated carbon imported from China in 2007, ranging from 49 to 228 percent (average 62 percent) on top of the regular 4.8 percent tax. Furthermore, due to the construction of hundreds of new power plants, China’s need for coal has been steadily expanding. Many coalmines were stopped at the same time for safety and environmental concerns, resulting in Chinese coal shortages and price hikes.

China also abolished the 13 percent value added tax (VAT) refund that AC exporters had got from their government, adding to the perfect storm’s combination of factors. Finally, owing to currency exchange rates, Chinese carbon costs have risen as the dollar has declined. As the price of coal soared in China, local manufacturers followed suit.

The government-ordered shutdown of most activated carbon facilities in China on May 31 for about three months, in an effort to minimize air pollution for the Olympics, is the cherry on top of the China coal AC cake. This will very definitely worsen the supply and cost of coal activated carbon. Furthermore, the cost of coal in China has nearly quadrupled in the last year, and China imported more coal than it exported for the first time ever last year.

We have enough of coal in the United States; domestic activated carbon companies have no trouble obtaining raw materials, but they are operating at full capacity. The additional capacity is mostly for powdered activated carbon, which will be used to address the impending mercury emission control market (mainly power plant flue gas). Coal AC pricing has grown quickly in the last year as a result of anti-dumping penalties, rising energy and labor costs, and high domestic production levels.

Scores of facilities in a dozen nations produce coconut shell activated carbon, which is imported into the United States through numerous resellers. It is suited for a wide range of applications and, for the first time, it is less costly than coal-based air conditioning. Bituminous AC carbon prices have risen due to a variety of causes (energy, labor, currency exchange rate, and so on); coconut shell activated carbon prices have risen as well, although not nearly as much.

Last Words

Because coconut shell activated carbon is less expensive than bituminous coal-based activated carbon, it is recommended to remove VOCs from drinking water in POU/POE systems. It has a higher hardness, produces less dust, emits less ash, and is more eco-friendly. The days of low-cost activated carbon are over, and it’s more important than ever to be sure you’re buying and using the proper Activated Carbon for the job. There are many different types and grades of activated carbon manufactured from diverse raw materials; talk to your activated carbon provider about your application and obtain the correct carbon to help you save money.