Activated carbon is a kind of carbon that can be manufactured from a variety of carbonaceous materials, including coconut shell, rice husk, coal, paddy husk, and wood. Coconut shells are suitable for creating high grade activated carbon due to their low ash level, high carbon content, and natural pore structure. Activated carbon made from coconut shell is said to be superior to that made from other sources because of their tiny macro-pore structure, which makes it more efficient for gas/vapor adsorption.

Coconut shell activated carbon aids in the elimination of color and odor from compounds, as well as serving as a pre-filter in the purification of water. Coconut shell activated carbon has a huge interior surface area, making it an excellent adsorbent for a variety of pollutants in drinking water. Therefore, coconut activated carbon manufacturers have to keep numerous factors in view during the production.

Application and Uses of Activated Carbon

- In both food and non-food sectors.

- In processing of chemical, sugar, and cooking oil purification.

- Used in waste-water and drinking water treatment.

- Bleaching and refining of vegetable oils.

- Recovery of solvents, such as gold and other vapors.

- In gas mask to protect against toxic vapors and gases.

Carbon Activation Process

Since steam activation process is commonly used to activate both coconut shell and coal-based carbons, Karbonous uses the same process using two-stage technique. To begin, the raw material, which is in the form of lumps, is carbonized by heating it in an inert environment, such as flue gas, to cause dehydration and de-volatilization of the carbon. The volatile component of the source material is reduced to less than 20% after carbonization. A coke with pores that are either too tiny or too limited to be utilized as an adsorbent is created.

The activation stage enlarges the pore structure, increases the internal surface area, and makes it more accessible in the second stage. Steam is used to activate the carbonized product at temperatures ranging from 900°C to 1100°C. The chemical interaction between the carbon and the steam occurs on the carbon’s interior surface, taking carbon from the pore walls and expanding the pores. The steam activation method enables for easy pore size adjustment and the production of carbons tailored to certain end-uses.

Steam activation produces activated carbon in 1mm to 3mm particles, which are crushed and screened to remove fines and dust to fulfil granular activated carbon requirements. The carbon particles are further ground using a mild crushing action to generate powdered activated carbons. Most coconut shell activated carbon suppliers demand the same properties of the activated carbon.

THE BENEFIT OF STEAM ACTIVATION

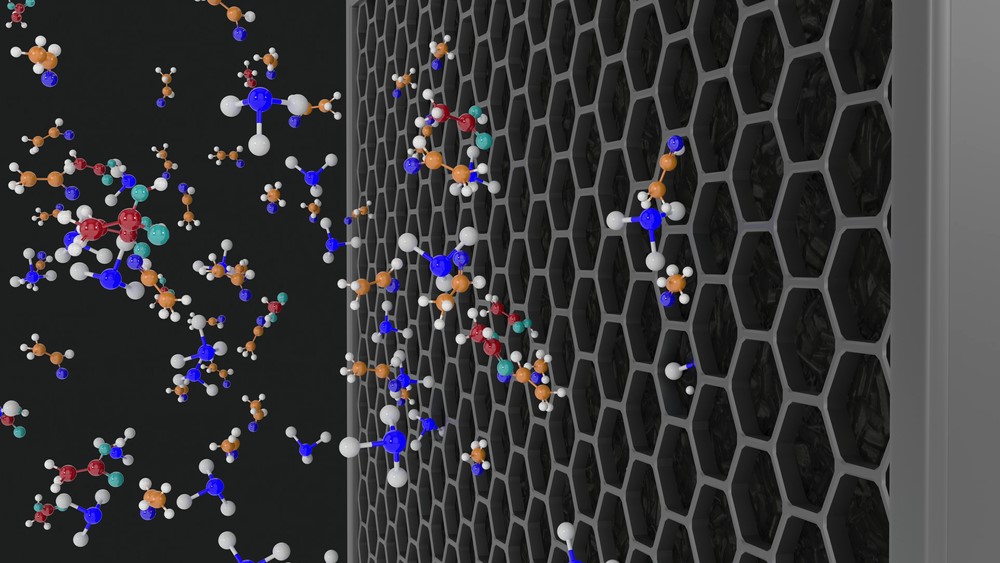

The activation process creates a network of small holes within and on the carbon surface with varying sizes that serve as a channel for water to reach the expanded internal surface generated by activation. Organic contaminants that attach to the surface of carbon have a natural attraction for it. When carbon is activated, it produces tiny holes and pockets that increase its surface area. On the activated carbon atoms at the pore wall surface, a force imbalance develops.

Activated Charcoal Can Also Help Your Teeth

If you keep yourself updated with the latest trends, activated charcoal is exploding in the cosmetic industry, especially for teeth whitening! There are numerous charcoal toothpastes available in the market to choose from, and they help your teeth stay clean. Activated charcoal is highly absorbent, which means it is very good at absorbing germs and bacteria in your mouth. Furthermore, the occasional use of charcoal toothpaste can help you remove stains from your teeth, making them look cleaner and more aesthetic. Users have also reported that using these every now and then has helped them overcome their bad breath problem significantly. However, according to Elite Dental Center, charcoal toothpaste is abrasive and should never be used daily. Daily use can lead to worn-down enamel, which causes teeth sensitivity and make your teeth look yellow instead of white and clean. So, make sure that you don’t overuse activated charcoal for cleaning your teeth, and you are all good to go.

Molecules are physically adsorbed, or attracted and held physically to the pore wall, to balance this imbalance (Van der Waals forces). For instance, pesticides, chloroform, and other pollutants slide into the holes of this honeycomb-like material and stick there through a process known as adsorption. The porosity of activated carbons provides a large surface area for this adsorption to occur. Adsorption takes place in holes that are slightly bigger than the molecules being adsorbed, which is why it’s critical to match the molecule you’re seeking to adsorb to the pore size of the activated carbon.

Activated Carbon Products at Karbonous

Our activated carbon products are made from natural materials including coconut shell, coal, and wood.

1) Activated Carbon from Coconut Shells

Coconut shell activated carbon is a vapor-activated substance produced from coconut husk. When used on a medium, this carbon will not contaminate or react with it because it contains no chemical agent. It’s everything but a completely normal and eco-friendly item with a low carbon footprint and the ability to absorb pollutants with a micro-pore molecular structure, such as those found in drinking water. Coconut shell activated carbon may securely support applications such as the recovery of gold and other precious metals due to its strong abrasion resistance and unique physical and chemical properties.

2) Activated Carbon from Coal

Activated carbon made from coal that has been steam activated is known as coal based activated carbon.

3) Activated Carbon – Water Washed

Karbonous is a water-washed, high-purity, high-activity granular activated carbon manufacturer, who carefully chose coconut shells using steam activation.

5) Activated Carbon from Wood

Wood Activated Carbon is an acid cleansed, high purity, high activity granular activated carbon made from carefully chosen coconut shells by steam activation.