For the removal of organic and inorganic substances present in solution, activated carbon is used, considered as one of the most versatile adsorbents present in nature.

The “charcoal” is obtained from wood, which we can define an ancestor of modern activated carbon, was already in use for medicinal purposes at the time of the ancient Egyptians (2000 BC); hints of the use of these particular carbons in the absorption of harmful gases have been reported in the literature by Scheele (1773 AD) and by Fontana (1777).

Porosity of activated carbon

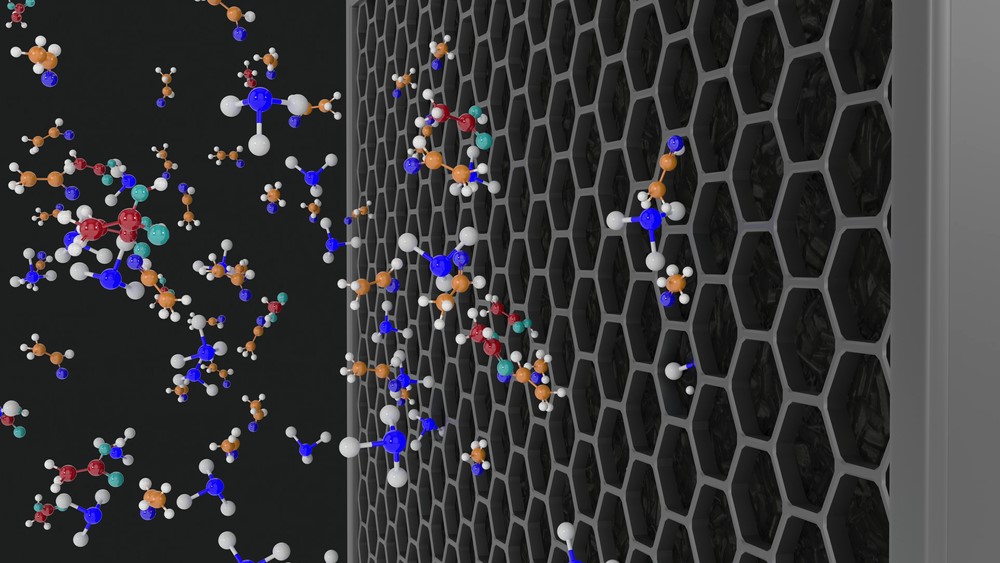

Activated carbon has a highly porous random structure, with a noticeable variation in pore size, it can range from small fractures to cavities reaching molecular size. It is also described as having a “creased” surface, in which the flat sheets are broken and curved back on themselves.

Intermolecular attractions in the smallest pores create the adsorption forces. These forces cause large and small molecules of dissolved contaminants to condense and precipitate from the solution into microscopic pores. Activated carbon is a good adsorbent because it has a large surface on which contaminants can adhere. We will see later how adsorption works in its various phases. However, activated carbon manufacturers know how to manufacture and what it takes to manufacture the particular grading of activated carbon according to their applications and use. It is important to note that each industry and type of process need varied, diversified, and different grading and types of activated carbon. Therefore, the manufacturing of activated carbon depends on the work process.

Two major activated carbon types

Two different forms of activated carbon are available: powder or PAC (Powdered Activated Carbon) and granular or GAC (Granular Activated Carbon). The GAC item also includes activated carbon in pellets.

The former is added to the water, mixed for a short period of time, and removed. Adsorption of the molecules occurs while the PAC is in contact with water. PAC is added quite early in the treatment process and then either settle in the basin where flocculation occurs or is removed during backwashing of the filter beds.

The granular activated carbon is generally used in beds through which passes the water or the air destined to the treatment. As the GAC filters, the surface inside the pores gradually becomes covered with chemicals until the carbon is no longer able to adsorb new molecules. At this point, the “exhausted” coal must be replaced with virgin coal.

Filtration through activated carbon

Reality is much more complex and articulated than what we see. The substances, liquid or gaseous, around us that we emit into the environment through our industrial processes are only a part of the complex elements and compounds.

Not all of the substances, some are unhealthy and dangerous for the environment, affecting the ecological cycle globally. This is why it is essential to apply filtration processes, which contribute to separating the polluting substances and helps easy and clean disposal of these substances. One of the most used materials infiltration processes for the purification of liquid and gaseous streams is activated carbon.

The adsorbing capacity of activated carbon

To understand how much (and which) substances can be retained by activated carbon, it is useful to underline their so-called adsorbing capacity. This expression refers to the quantity of material that the activated carbon is able to adsorb. This value is conditioned by several factors: the surface area of the activated carbon, the temperature, the type of pollutants and their molecular weight, the presence of humidity, and the pressure.

When analyzing, comparing, and evaluating activated carbon, it is necessary to evaluate the so-called adsorption classes, i.e., the ability to adsorb a certain pollutant. We can find the following adsorption classes towards the different types of pollutants:

- Class A – Adsorption capacity between 20% and 50%;

- Class B – Adsorption capacity between 10% and 25%;

- Class C – Adsorption capacity less than 15%;

- Class D – Zero adsorption capacity.

To give an example in class A belong substances such as aromatic hydrocarbons, tar, liquid fuels, lubricants, greases, oils, odors, paint vapors, etc. Such a large selection of substances reveals the potential of activated carbon and its transversal use as filter products.

The applications of activated carbon filter systems

The most common use of activated carbon is for the treatment of water and gases. However, it is necessary to distinguish in order to know the actual uses of these materials. In addition to the uses in drinking water systems (those usually best known), there is a wide sector of industrial applications (both for small businesses and for larger factories) that benefit from this type of device.

Gas stream purification systems

For the purification of gaseous streams, activated carbon filtration systems are used for the recovery of solvents and organic vapors, for the purification of carbon dioxide from fermentation processes, the elimination of household, clinical, and chemical waste derived from incineration, as well as for natural gas purification and deodorization of vent gases. They are also used for the purification of biogas and biomethane, streams containing mercury, ammonia and other inorganic pollutants.

Liquid purification systems

As far as liquids are concerned, on the other hand, advantages can be obtained in the treatment of wastewater, in the purification of drinking water, and in that of underground water reserves from industrial contamination. There are also applications for the removal of organic pollutants, for the elimination of unpleasant tastes, dechlorination, the elimination of toxic compounds from wastewater, and the filtration of swimming pools and aquarium water. Without forgetting the use in treatments to avoid the formation of foams and the discoloration of food liquids (wine, fruit juices, oil) and pharmaceutical products.

Food and pharmaceutical purification systems

In addition to the filtration capabilities of gaseous and liquid streams, these products are excellent and widely used for the discoloration of oils and fats, wine and fruit juices for the removal of impurities and color in pharmaceutical products and, again, for the adsorption of PAHs (Polycyclic Aromatic Hydrocarbons) in oils.